Before

After

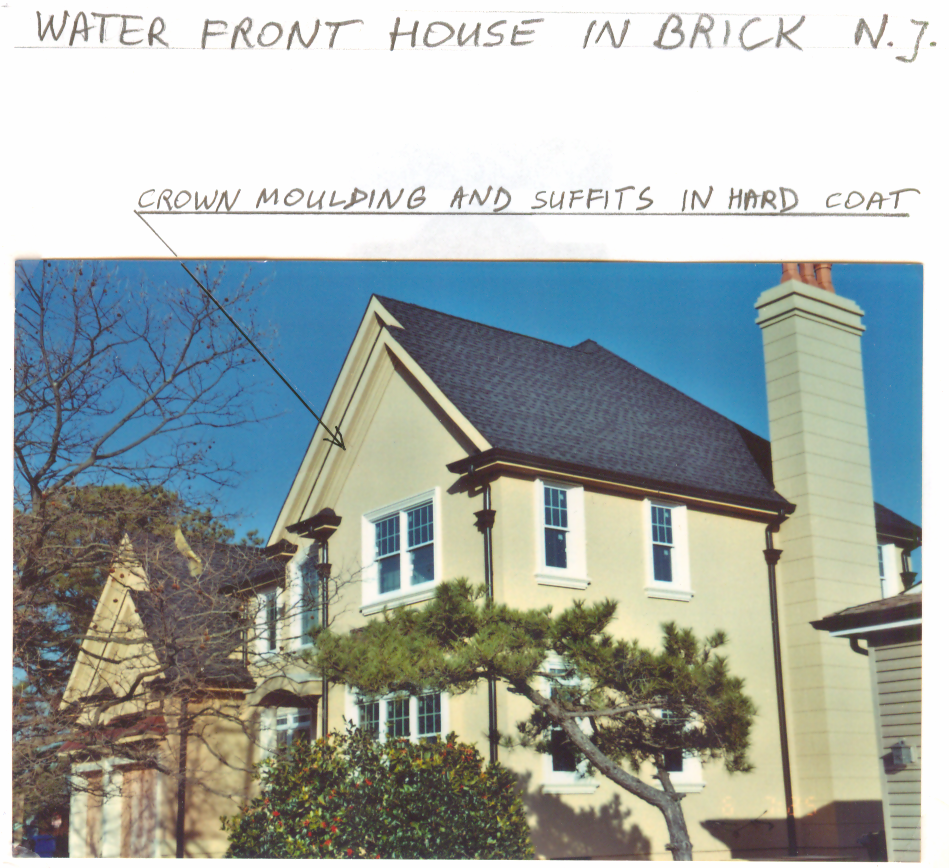

It looks like a million dollar facade; actually, the cost was a small fraction of it.

We specialize in existing buildings and houses and new ones under construction.

Besides new facade materials, our work may include wall modifications, window replacement or repairs, restoration or rejuvenation of deteriorating old finishes. Flashings, roof edge, capping, chimneys, and heavy gauge metal caps with high wind pins.

Everything is fused in an integral, waterproof facade that can last more than 75 years maintenance free and still look good, enhancing the value of the property.

This knowledge comes from years of observations:

– How buildings and houses age, why in some instances 100 year old buildings look better than 10 year old ones

– How the elements work and cause discoloration, effloresence, erosion, water infiltration issues

– Why sometimes the most expensive remedy is the worst and creates more costs down the road, not to mention aesthetics

In Section “B” you will find photos and comments describing common problems and how they can be avoided. Some interesting cases illustrate that savings of $15,000 during construction can later cause losses of $500,000 and perpetual maintenance of an ugly building.

A. Below find a small number of photos of completed jobs. For more photos visit the archive gallery with hundreds of photos.

Contemporary house in Short Hills

Another house in Short Hills

On sidewalks, we use 32″ wide scaffold frames. They take up only a narrow part of the sidewalk; no need to build expensive bridges.

Portico in Essex Fells

Antique Portland cement plaster and antiquated precast

Commercial building

School recladding

Flat but interesting

Natural stone portico

Note: there is no vertical mortar joint at the bay window 135° angle. Corinthian column capitals support abacus plaster plate.

B. Below find photos and comments describing types of failure and possible remedies

Portland cement stucco mixture too rich and corrosion of metal lath

Not all inventions are durable. This product design and application were defective. The school owner had to pay more than a million dollars to remove the material, fix the leaks, and install a new system.

We know how to fix it. Another coat of paint will only accelerate delamination. At this stage there is still time to fix it by spending $10,000 instead of $100,000 after a few years.

Water damage

The principle of efflorescence formation shown on frozen chicken broth: when material freezes, thin ice sheets like knives create capillary suction between the sheets, which pulls up a “flower” (the word efflorescence comes from the Latin word for flower). After thawing it leaves ugly residue and deteriorates walls. Porosity of material is also a major factor.

Efflorescence in action

At this stage repairs can cost $6,000. A few years later it could be $60,000.

A 6 year old job: the owner saved $4,000 on proper details. In a few years it will be a $60,000 repair.

A 5 year old job: cracks and delamination already visible

Another coat of paint will not solve this.

The owner of this huge brick building had very good taste for brick aesthetics. He picked one of the best looking, high end expensive bricks. But “a little money” was saved during construction on addressing long service and good looks. The 14 year old building is haunted by leaks, delamination, efflorescence, erosion, cracks of different origin like:

– thermal movements of steel and brick

– flexing of steel, not rigid enough

– settling down of bricks, water penetrations

$750,000 of beautiful brick work is now painted with elastomeric paint and looks ugly.

Efflorescence seeping through the paint

Not enough adhesion of plaster

Concrete block cracks telegraph through stucco due to water penetrations and corrosion (green color)

6 year old building, problems visible already

Portland cement plaster not compatible with this type of brick

Wire lath not embedded in mixture and corroded: a common problem. When water infiltrates, the process accelerates.

Example of corrosion damage. The volume of rust material that is made by steel subject to corrosion is 9 times bigger than the original volume of the steel itself. It pushes out all surrounding materials, which causes damage.

It is a big ticket job to do new steps. To do repairs every 2 to 3 years is not easy. The problem could be solved by using a pedestrian or automobile traffic bearing membrane with anti-slip sand or aggregate embedded in the top coat. Not all concrete can use it, though. In such cases, penetrating sillane could be used.

Putting anti-slip sand over top coat of pedestrian grade membrane.

Remediation of rotted wood

Contact

Email: office@superbfacade.com

Telephone: (973) 599-1008

Address: 401-R Rte. 10E Whippany, NJ 07981